|

EZ Emergency

Well Pump Kits. |

|

Pump Installation

Instructions |

|

Please Read

Carefully.. |

|

|

|

Our kits

are really very easy

to assemble and

install.

If you can drill a

couple of holes and

glue PVC pipe

together...you can

easily install your

hand pump. Our kits

are really very easy

to assemble and

install.

If you can drill a

couple of holes and

glue PVC pipe

together...you can

easily install your

hand pump.

Once you have

everything laid out

on your lawn,

everything will come

together.

Just take it one

step at a time...

We

Offer Great Support

If You Need Help

Installing Your E-Z

Water Well Hand

Pump,

I'M

THERE FOR

YOU AT EVERY STEP, 6

Days A Week.

Phone John Tatman @

Cell#

1-409-554-3628

If You Have

Questions During

Assembly &

Installation - 9am

to 5pm Central Time,

Mon thru Sat. |

|

|

|

|

|

IMPORTANT:

Do Not

Purchase Schedule

40

Pipe

For The 1" Outer

Casing Pipe...The

1/2" Pumping Pipe

Couplers Won't Fit

On The Inside Of A

1" Schedule 40 Pipe.

Here's What You

Need:

For

The Outer Casing

Pipe, You Need

1" Thin Wall

Pipe 200 psi

From

Lowes,

Home Depot or

Menards in

the Midwest, or your

local hardware

store.

Lowes

is your

best bet

to buy the 1" "Thin

Wall" 200 psi pipe

required for the

pump outer

casing...Lowes

stores stock it

nationwide, but call

before you make the

trip and ask for

Item #23993.

Charlotte

Pipe 1-in x 10-ft

200-PSI SDR 21 PVC

Pipe. To save

time, go to

your local Lowes

website and type in

Charlotte

Pipe 1-in x 10-ft

200 Psi Sdr 21 White

Sdr 21 PVC Pipe.

It'll tell you the

quantity in stock

and the aisle

number. If it's out

of stock, check

another Lowes, Home

Depot or Menards if

you're in the Mid

West.

![]()

In

the Midwest you can

try Menards,

you'll need 1" x 10'

Sdr. 21 Plain End

Pipe...Model

Number:

1x10sdr21PE

Ask For

SKU:

6899697![]()

At Home Depot

it's called 1 in. x

10 ft. Plastic Plain

End Pipe - 200 psi

Thin Wall.

For the inner

pumping pipe,

use

1/2" Schedule

40

in10' lengths. Always in stock

at most stores.

NOTE:

On VERY RARE

occasions, your

local Home Depot or

Lowes might be out

the 1" Thin Wall

pipe. Not To

Worry...our

Kit can easily

be adapted to use 1

1/4" Schedule 40

pipe. Call me about

this and I'll give

you easy

instructions,

If you have any

questions, give me a

call.

|

|

Go Ahead And Preview

This Page, But

Come Back To These

Links

To Get Started:

OTHER LINKS

#1

First, Build Your

Pump Handle

>>

#2

Then

Build Your Support

Unit At Your Well

Cap

>>

#3

Wooden Installation

Support Block

>>

#4

Detachable Pump

Handle Section

>>

Installing

In A Well House Or

Indoors/basement

>>

A

vast majority who

purchase our Pump

Kits simply store it

with all the piping,

fittings and PVC

Cement until it's

needed in an

emergency. If this

is your plan, I

suggest purchasing a

30 gallon potable

water drum and

siphon hose from

www.beprepared.com

and store water for

a short term

power outage. Then,

if needed you can

install your hand

pump for a long

term power

outage. (add a can

or two of PVC Cement

once a year and

store it indoors,

not in the garage

where it might dry

out) |

|

Please Note:

You may

detect a slight odor

of PVC cement when

you open your order.

Not to worry, this

is normal and will

eventually go away.

PVC cement is used

worldwide everyday

in water well

installations and

will not harm your

well water.

Test Your Pump

Piston:

All pistons are air

tested several times

during assembly,

however it's

advisable to test it

prior to

installation. It may

have been damaged

during shipment.

Simply test it by

pumping the 1/2"

pipe in a 5 gallon

bucket of water

filled to the top.

You'll be pleased

with its

performance. |

|

|

|

![]() |

|

|

|

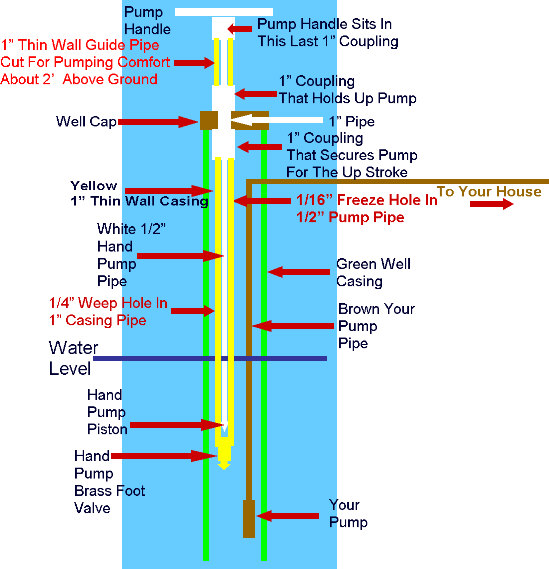

A Diagram Overview

Of How It Works

NOTE:

Regarding

Freeze Hole:

Once your pump is

built as per our

instructions, it

will have a

1/4"

weep hole on one

side of the

larger 1" Thin Wall

outer casing pipe

(pictured in yellow)

say 5'

or so above

your static water

level that drains

any seepage back

into your well. This

keeps the outer

casing free of water

below the freeze

line. The smaller ½”

pumping pipe

(pictured in white)

will have a 1/16”

hole drilled on

one side of the ½”

pipe, 5’ to

10‘ below

ground level

and below your

freeze line.

(You must determine

your freeze line)

This allows

the water in the ½”

pump handle pipe to

drain into the 1"

Thin Wall casing

pipe, then the 1”

casing pipe drains

out of the 1/4" weep

hole back into your

well.

Simple and 100%

Freeze Proof.

The pump handle and

above ground outer

casing pipe should

be removed when not

in use and your well

cap should be

properly insulated

against any

very extreme

cold

temperatures.

IMPORTANT: IN

EXTREME COLD TEMPS I

Recommend Putting 1"

Black FOAM

Insulation on the

last BELOW GROUND

section

of the larger 1"

Thin Wall outer

casing pipe. Wrap it

tightly with Black

Gorilla Tape so it

won't slide. Put the

insulation starting

from the bottom of

your well cap to at

least below your

freeze line.

|

|

![]() |

|

|

|

|

|

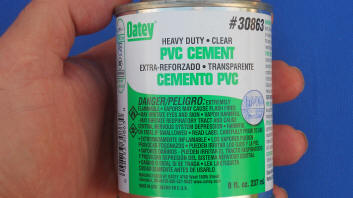

Get the medium

size (8 oz)

can of PVC

Cement...The large

can applicator is

too large

for our smaller

pipe. |

|

VERY,

VERY IMPORTANT:

Use

a cotton swab

(Q Tip)

when

applying cement to

the

INSIDE

of the 1/2"

couplers and 1"

couplers so you

don't apply too much

and restrict the

water flow.

Use the

can

applicator on

the

outside

of both 1/2" and 1"

pipe...The

Q Tip will give you

a good coating

on the inside

of couplers and then

the can

applicator, will

give you a

THICK COATING

on the outside

of both pipes.

Always give the

connections 1/4 turn

when cementing PVC

pipe together.

This helps the PVC

cement to be spread

evenly for a secure

fit. Be sure

to wipe away any

excess PVC cement

with paper towels

and discard

properly.

IMPORTANT...Too much

PVC Cement on the

inside

of the

1/2" couplers

could cause your

1/2"

pumping pipe

to be

blocked and your

hand pump will not

work properly, if

at all. |

|

|

|

Let's Get Started:

You will need a

Hacksaw,

Knife, 1/4"

Drill Bit ,

1/16" Drill Bit

and

Heavy Duty Clear Medium Size Cans of

PVC Cement ...I

never use

primer...it's really

not needed for

smaller pipe |

|

|

|

IMPORTANT:

Average Handling/Set

Up Times for PVC/CPVC

Solvent Cements

Handling/Set Up Time

is the time required

prior to handling

the joint.

In damp or humid

weather, allow 50%

additional time |

Temperature

During

Assembly |

Pipe Diameter

1/2”

to 1" |

|

60° -100°F |

2 minutes -

I would wait

10 minutes

for each larger 1"

coupling fitting

cement to cure,

especially on deeper

wells. |

|

40° - 60°F |

5

minutes |

|

20° - 40°F |

8

minutes |

|

0° - 20°F |

10 minutes |

|

|

|

First,

You'll Need To

Determine Your

Static Water Level

Before Purchasing

Your Pipe and

Fittings.

It's IMPORTANT To

KNOW

Your Water Level

In Your Well Pipe

Before Proceeding

With Anything...

Don't Depend On Any

Paperwork Your Well

Driller Gave You

Years Ago...Your

Water Level May Have

Changed... You DON'T

Want To Install Your

New Pump And Be Just

Short Of

Water...It'll Only

Suck Air If That

Happens.

Measure It

Yourself...TWICE

You may have a 350'

well, but your

static water level

is much closer to

the surface.

To find your static

well water level,

You'll need

a

fishing

bobber.

They are

normally red on

bottom & white

on top. (Wal

Mart, fishing

dept),

you'll need

a

large washer,

next get

some twine/string,

(not too thick)

say 100+

ft. Now

you are going

fishing...so to

speak. :-)

Tie the

washer to

the end of the

twine/string.

Next tie the

bobber about 6

inches to a

foot above the

weight. Now

lower

that down your

well

opening...the

bobber will

float when it

hits water and

go slack...you

should feel it

get lighter...(Make

Sure It Is

Hitting

Water...bob it

up and down

rather quickly ,

you should hear

a blooping sound

as the fishing

float hits the

water) then

pull it

tight to take

out the

slack...mark it

at top of well

opening

by pinching

a piece of tape

around the twine...pull

the

fishing bobber

out...lay

twine/string

on

the the

ground and

measure. That is

your static

water level.

|

|

|

|

|

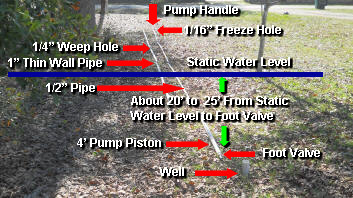

After Finding Your

Static Water Level.

If you have a 2"

well opening, I

recommend figuring

at 20' to 25' deeper

from your static

water level down to

the EZ pump piston

brass foot valve.

Here's why...The

recommended

20' to 25'

below static water

level is to give you

enough water in

your well

casing to pump up.

For example; My well

is 350' deep

and has a

static water level

of 37'...but it's

only a 2"

well casing.

So this allows me to

pump around 9 or so

strokes before I

draw down the water

to the foot valve

and it starts

sucking air. A 2"

well can only hold

so much water

at 27 feet below

static water level.

However, my water

recovery rate is

good. All I do is

wait less than a

minute and the water

level is back up and

I can start pumping

again.

This is

much less

critical in a 4" or

6" well because

they hold more water

in the well casing.

The 25' is NOT

written in stone.

With a 6" well, you

can put the foot

valve

15' below

static water

level...It's really

no big deal...Just

go as deep as you

can down to say 15'

to 25'.below static

water level. |

|

|

|

![]() |

|

|

|

Buying Your Pipe:

Our Pump Piston uses

1" THIN WALL PVC -

200 PE

Pipe At Lowes or

Home Depot,

for the outer

casing and 1/2" PVC

Schedule 40 for the

inner pumping pipe.

I recommend Lowes

if you have one near

you. Purchase in 10'

sections. The pump

piston cylinder is

around 3' long and

the handle section

is about 2' tall

above ground, so if

you are going down

about 70' all you

need is 7 -

10' pieces of

both pipe sizes...1"

Thin Wall and 1/2"

Schedule 40 PVC

pipe..

If you should need a

few more coupling

connectors, you'll

need 1" & 1/2"

couplers.

Let's lay out the

pump.. |

|

|

|

If Installing In a

Well/Pump House,

Basement Or Under

Any Roof,

See This Diagram

and Call Me With Any

Questions |

|

|

|

Cement one coupler

fitting to all 10'

sections of pipe on

the upper ends, both

1/2" and 1" pipes,

facing the pump

handle,

No Need For The

Primer...

|

Photo of pipe and

Support Section |

|

|

|

![]() |

|

Lay all piping out

so you can see how

it goes together and

to help keep you

organized

When laying out your

pump, start at the

bottom of the EZ

pump piston cylinder

and work your way up

to the pump

handle, as seen

in this photo. |

|

|

|

|

VERY IMPORTANT:

Drill your 1/4"

Weep Hole and 1/16"

Anti Freeze Hole

while you have it

laid out on the

ground. See detailed

descriptions below. |

|

|

|

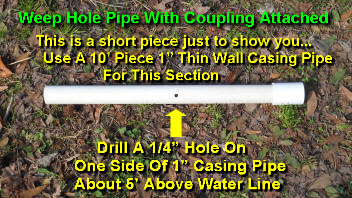

The All Important

1/4" Weep Hole Pipe

AND 1/16" AntiFreeze

Hole |

|

|

IN ADDITION

To The 1/4" Weep

Hole At Left, Drill

a 1/16" hole

ON ONE SIDE

of the last piece of

1/2" Pumping Pipe a

few feet below your

freeze line. This

will allow drainage

from the pumping

pipe as shown in the

above pump diagram. |

|

The pipe shown above

is a short piece for

illustration. Use

a 10' section.

|

|

|

|

Before attempting to

drill the holes, use

a small nail and tap

it with a hammer a

few times to make an

indentation in the

pipe, so the drill

bit won't slide

while you are trying

to drill the holes. |

|

|

|

Weep Hole Pipe:

See The Lay Out

Photo At The

Beginning:

Drill a 1/4"

hole ON ONE

SIDE in the

center of one 1" 10'

pipe. Put this pipe

between your static

water level and the

pump handle. The

hole should go about

5' or so above

your static water

level. The weep

hole is to drain any

seepage out of the

1" Thin Wall pump

casing back into

your well.

Then drill

the 1/16" antifreeze

hole a few feet

below your freeze

line. Be sure to get

any drill

shavings out of the

pipe. Push a rag

through the 1" pipe

with a 1/2" 10' pipe

to clean it out.

REMEMBER to include

both holes in the

assembly. VERY

IMPORTANT |

|

|

|

![]() |

|

|

|

A ladder to assist

is optional - it

helps with a 1

person install. |

|

A ladder was

sometimes used when

installing the

heaver piping we

used in the past...I

left these photos in

for your

consideration...no

need to cut a hole

in your ladder...if

you use one,

stand the ladder

upright and simply

tie the pipe to the

side of the ladder

with a short piece

of rope. |

|

|

|

|

|

When everything is

laid out: Let's get

started |

|

|

|

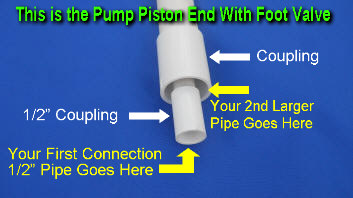

This Is The

Connecting End Of

The Pump Piston |

|

|

|

|

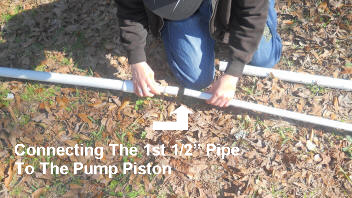

To begin:

Cement the

first 10' section

of both size pipes

on the ground, then

insert 13' section

(3' Piston plus 10'

section) in well

pipe.

All other sections

will be

attached/cemented

vertically

|

|

|

|

![]() |

|

|

|

|

|

|

|

Begin Assembly:

Attach your first

pipe. Apply PVC

cement to the inside

of 1/2" coupling

that is already

attached to the EZ

piston cylinder

pipe. Then apply the

cement to the

outside of your

first smaller 1/2" X

10' pipe.

|

|

Connect the two by

pushing them

together tightly and

turning about

1/4 turn.

The turning helps

spread the cement

evenly. It's

important for a 1/4

turn on all

fittings. |

|

|

|

![]() |

|

|

|

Next,

your

first larger

pipe:

Take the 1" Thin

Wall X 10' casing

pipe and slide it

over the 1/2" pump

pipe. When the 1/2"

pipe is in the 1"

pipe, there is

little room for the

PVC cement

applicator to fit

into the 1" coupling

to swab with cement.

Simply try to

coat as best you can

the

inside lip

of the 1" coupling

without getting too

much glue on the

1/2" pumping pipe...(use

a cue tip cotton

swab bent a little

at a 45 degree

angle, it's smaller

than the can

applicator).

Then coat the

outside of the

1" casing pipe

thoroughly with

the PVC cement can

applicator

and connect to the

1" coupling on the EZ piston cylinder.

Push in hard

and make

1/4 turn.

Remember,

use

a cotton swab

when applying cement

to the

INSIDE of the 1/2"

couplers

so you don't apply

too much and

restrict the water

flow.

Use the can

applicator for

outside of both 1/2"

and 1" pipe...Apply

liberally on the

outside of both

pipes.

The PVC

cement must be

spread evenly for a

secure fit.

Take Your Time With

This. |

|

|

|

|

Now you have the

first 10' section of

piping cemented to

the 3' pump piston.

Install this

first assembled 13 '

section

into your well using

the wooden support

block. Then you add

10' sections

vertically as you

lower piping into

well.

|

|

|

|

![]() |

|

|

|

Attach the next

vertical

section |

|

|

|

![]() |

|

|

|

The Channel Locks

are used in a 1

person install.

I recommend 2 people

for the install on

deeper wells with

more than 75' of

piping. As you add

pipe, you'll need

someone to move the

wooden support to

the next 1" coupling

as you lower the

piping

and to help with the

weight as you add

more pipe. |

Insert the 1/2" pipe

into the 1" pipe on

the ground and clamp

on the channel locks

(IF A ONE PERSON

INSTALL)

as seen to left.

Then raise to

vertical position

and cement the 1/2"

pipe. Then remove

channel locks and

cement the larger 1"

pipe.

Be sure to cement

the inside and

outside of all pipe

casing.

Remember , TAKE

YOUR TIME AND THINK

EVERYTHING THROUGH.

The red handle clamp

is optional

and is simply used

to hold the 1/2"

pipe a little higher

while cementing. OR

another person

helping can hold up

the pipe while you

glue/cement.

Also optional

but recommended

is a nylon or

polypropylene rope

tied securely to the

pump piston just

under the larger 1"

coupler and anchored

to a ladder or

stationary object,

as seen to left as a

safety line. After

install, simply tie

off around the lower

well pipe and leave

in place.

Let the PVC cement

cure (dry) for

at least 10

minutes

before lowering each

10' section into

your well. |

|

|

|

Simply

repeat the process

all the way up To

The Top T Handle.

|

|

![]() |

|

|

|

|

|

This photo shows

completed pump...before

channel locks were

removed and "T"

handle is pushed

down.

|

|

|

|

![]() |

|

|

|

Pumping:

The pump stroke

should not

be fast and jerky.

The most efficient

way to pump is a

smooth straight

up stroke then

push straight down

smoothly then pull

straight up

smoothly. |

|

|

|

You are finished,

Done...Pat yourself

on the back, you

deserve it.

Now a sincere

personal note. This

may sound hokey, but

the very first water

that comes out of

your hand pump will

give you a feeling

of self reliance and

security, knowing

you have prepared

for your family one

of the most

important things for

survival...water.

It's a great

feeling. |

|

|

We

Offer Great Support:

If You Need Help

Installing Your E-Z

Water Well Hand

Pump, Call

1-409-554-3628

9am to 5pm, Mon to

Sat

After hours

Email Our Help Desk.

WE ARE

THERE FOR YOU AT

EVERY STEP. We

Offer Great Support:

If You Need Help

Installing Your E-Z

Water Well Hand

Pump, Call

1-409-554-3628

9am to 5pm, Mon to

Sat

After hours

Email Our Help Desk.

WE ARE

THERE FOR YOU AT

EVERY STEP. |

|

|

|

|

|

|